Introduction

Introduction

The earliest drivers and sensors were created using electromechanical techniques. They are relatively big and expensive to manufacture, making them unsuitable for consumer electronics downsizing. Since the late 1980s, with the rapid development of the integrated circuit industry, the trend of integrating drivers and sensors with chips has been unavoidable with scientific and technological development, resulting in the birth of MEMS applications, the most common of which is the MEMS microphone. Condenser microphones have long been utilized in electronic goods, such as electret microphones (ECMs), which are typically found in mobile phones.The structure of an electret microphone is basically a sound chamber made of sealed circuit boards surrounded by a cylindrical enclosure. Basic sound chamber components such as the diaphragm and rear plate are installed. The design space for microphones is shrinking as electronic items continue to be miniaturized. A smaller diameter diaphragm means sacrificing the microphone's acoustic performance. In this scenario, MEMS microphones with smaller sizes and greater performance are becoming increasingly popular among terminal makers. MEMS microphones have mostly supplanted traditional electret microphones in mobile phones, according to acoustic equipment makers such as KNOWLES, Goertek, and AAC.

However, the production of MEMS is a very complicated process with stringent environmental constraints. Manufacturers should focus on the following aspects:

1.Micron or micro-nano precision parts in MEMS devices are extremely delicate. During the packaging process, components must withstand the temperature impact of procedures such as reflow soldering. How can packing minimize stress on devices?

2. The incompatibility between a clean packing environment and a micro actuator that is not totally sealed. MEMS devices are particularly sensitive to dust, thus it is critical to avoid pollution throughout the production process. However, in addition to electrical signals, the MEMS sensor chip contains various physical signals that must be communicated with the outside environment, such as light, sound, force, magnetism, etc. On the one hand, MEMS devices should not be entirely sealed, but rather have open passageways for signal transmission.

3. Testing during packaging. Mechanical property changes, chemical contamination, air tightness, vacuum degree, thermal matching, and other factors encountered throughout the packaging process will all have an impact on MEMS sensor performance. To avoid batch scrapping, in-process testing is very critical.

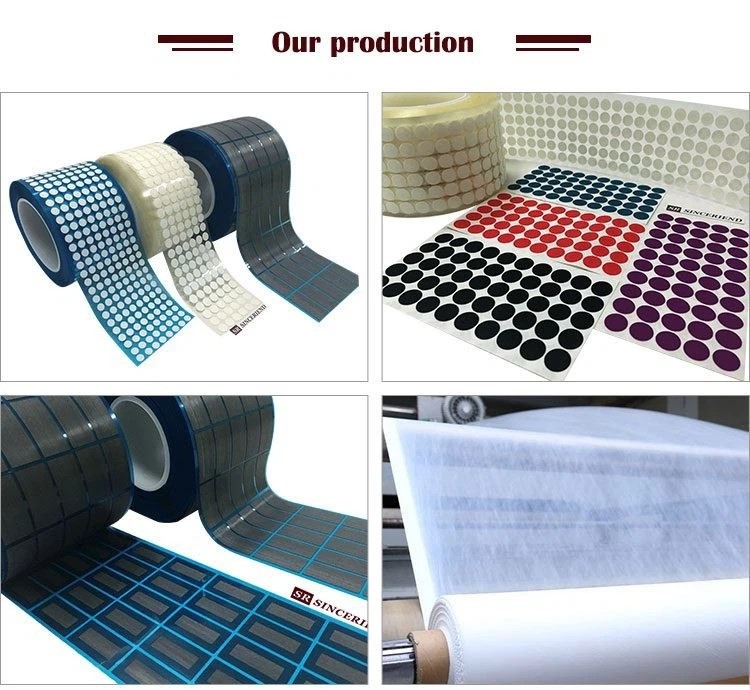

Sinceriend has collaborated extensively with MEMS device suppliers. With many years of experience in ePTFE R&D and application, Sinceriend has successfully launched a dust-proof breathable membrane specifically used for protection in the MEMS packaging and patch manufacturing process, which can effectively solve the problems of pressure accumulation, dust pollution, and process testing in MEMS manufacturing, and greatly improve the productivity and yield of MEMS manufacturing;

Feature

Sinceriend provides dust-proof, breathable, and sound-permeable MEMS products for various customer processes. The product has the following features:

1. Customized typesetting enables large and completely automated production for SMT and MEMS device manufacturers.

2. Temperature resistance up to 260℃*60s, suitable for demanding operating environments;

3. Meets manufacturer's protection standards for MEMS microphones by providing excellent air permeability, sound transmission, and dust resistance.

4. Consistent dependability for MEMS sensors.