Introduction

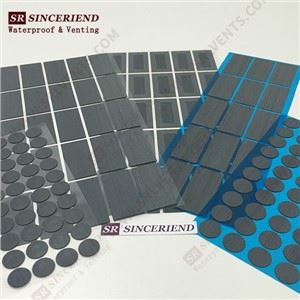

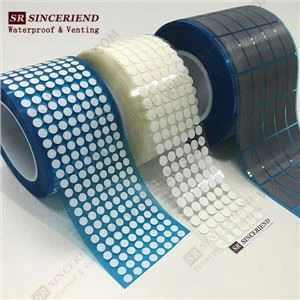

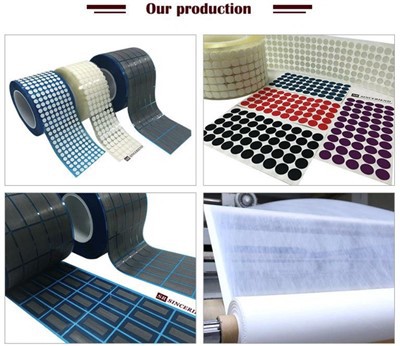

Products Description

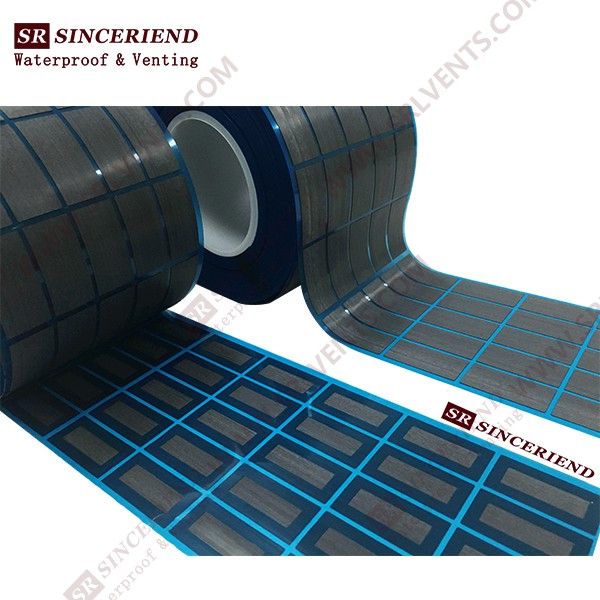

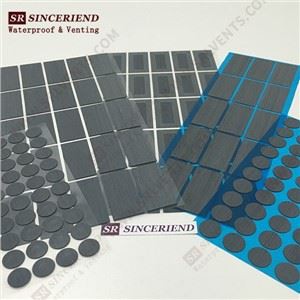

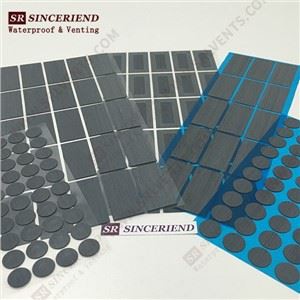

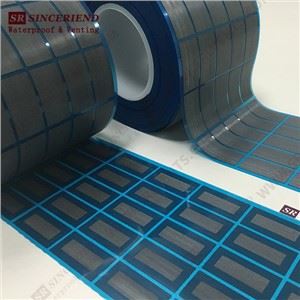

EPTFE Breathable Membrane Film is a membrane material with unique qualities that allow air and vapor to pass while remaining waterproof and dustproof. The membrane has distinct qualities that block moisture while enabling it to escape, making it both breathable and pleasant. It is widely employed in a range of applications, including waterproof and breathable textiles, filtration systems, medical equipment, electronics, and environmental protection.

Feature

1. Breathability: The ePTFE membrane features a microporous structure that allows gas to pass through but prevents water molecules from passing through, making it both waterproof and breathable.

2. Chemical resistance: Because ePTFE membrane has high chemical resistance and can withstand most chemical erosion, it is commonly used in filtering and separation technology, particularly in settings that demand corrosion resistance.

3. High temperature resistance: Because ePTFE membrane can endure high temperatures (up to 260°C) for extended periods of time, it is commonly employed in high temperature industrial applications.

4. Low friction and self-cleaning: Because ePTFE membranes have a low friction coefficient, dirt does not easily accumulate on their surfaces. The ePTFE membrane has exceptional self-cleaning qualities and effectively reduces dirt adherence.

5. Excellent mechanical properties: The ePTFE membrane has a high tensile strength and tear resistance, ensuring that it is not readily destroyed after extended use.

Application

The installation of Sinceriend ePTFE electronic breathable membrane film is a critical step in the electronics manufacturing process. They are commonly used in various industries including consumer electronics, automotive, medical devices and industrial equipment. The selection of an appropriate vent depends on factors such as the required airflow capacity, environmental conditions and the specific requirements of the application.

Cleaning and Maintenance

1. Regular cleaning: Clean the ePTFE membrane's surface with warm water and mild detergent. Avoid detergents that include bleach or other strong acidic or alkaline chemicals. Strong chemical components may cause damage to the membrane's surface structure.

2. Avoid using laundry detergent and softener: These detergents may clog the membrane's micropores, reducing air permeability. These substances should be avoided during cleaning.

3. Hand wash or use a gentle washing machine mode: If the item is machine washable, such as clothing, wash it gently (low speed, low temperature water) to avoid destroying the membrane's structure.

4. Drying after cleaning: After cleaning, try to avoid direct sunlight. You can let it dry naturally or use low-temperature air drying. High temperatures and intense sunshine will cause the membrane to degrade.

Storage Precautions

1. Avoid heavy pressure: To prevent long-term deformation caused by heavy pressure, avoid placing the membrane under heavy objects during storage. This will compromise the membrane's air permeability and structural integrity.

2. Avoid humid environments: Excessive humidity might cause the membrane material to grow damp, compromising its function. It should be stored in a dry, well-ventilated area.

3. Avoid direct sunlight: The ultraviolet rays of sunlight will hasten the aging of the ePTFE membrane, therefore avoid exposing it directly to sunlight, especially if it has not been used in a long time.