Introduction

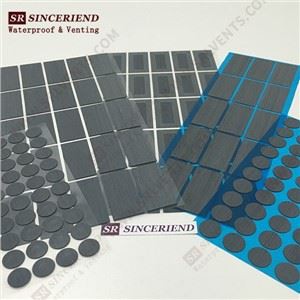

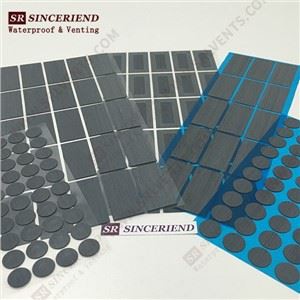

Products Description

Acoustic vent membranes, commonly known as acoustic grilles or speaker grilles, are essential components of modern audio systems. It permits sound waves to pass through while preventing particulate matter from entering the speaker housing or duct, potentially improving sound quality and performance. It is commonly used in headphones, speakers, and other audio devices to control audio output.

Products Description

1. Effective ventilation

Acoustic Vent Membrane has good air permeability, which allows for unrestricted circulation of air and meets indoor ventilation requirements.

2. Excellent sound insulation effect

The unique acoustic structural design efficiently blocks the propagation of noise.

3. Waterproof and dustproof

It has good waterproof properties and can keep rain and moisture out of the space.

4. Durable and dependable

Made of high-quality materials with excellent corrosion and wear resistance.

5. Easy installation

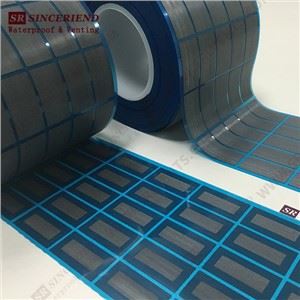

Installation is quick and easy, as it can be cut and spliced to meet specific needs.

Installation method

1. Preparatory work

Determine the installation location, then clean the surface to ensure it is flat, dry, and oil-free.

Prepare the instruments required for installation, such as scissors, screwdrivers, sealants, and so on.

2. Measurement and cutting.

Measure and cut the Acoustic Vent Membrane to fit the installation location. To reduce waste of materials, ensure that the cutting size is accurate.

3. Installation and fixing

Attach the cut Acoustic Vent Membrane to the installation surface and secure with sealants or screws. Ensure that the membrane adheres tightly to the installation surface, with no gaps.

4. Inspection and Debugging

After the installation is complete, ensure that the Acoustic Vent Membrane is securely fastened and that there is no looseness or air leakage.

Perform ventilation and sound insulation testing to ensure that the product's performance satisfies the specifications.

Precautions

1. Sharp objects should not be used to scrape or damage the acoustic vent membrane during installation.

2. During installation, ensure that the front and rear of the membrane are properly aligned to avoid disrupting ventilation and sound insulation effects.

3. Conduct regular performance checks on the acoustic vent membrane. If it has been damaged or is aging, it should be replaced as soon as possible.

4. When cleaning the acoustic ventilated membrane, use a soft wet cloth to gently wash it down and avoid using chemical cleaners or harsh detergents.