Introduction

LED Protective Vents are ventilation devices built exclusively for LEDs. They are primarily used to protect LED bulbs and their internal electrical components from the outside environment, to maintain proper heat dissipation performance of the equipment, and to prevent pollutants such as dust and moisture from entering the interior. LED lamps are frequently utilized in a variety of settings, notably outdoors, industrial, or damp situations, hence their protective design is critical.

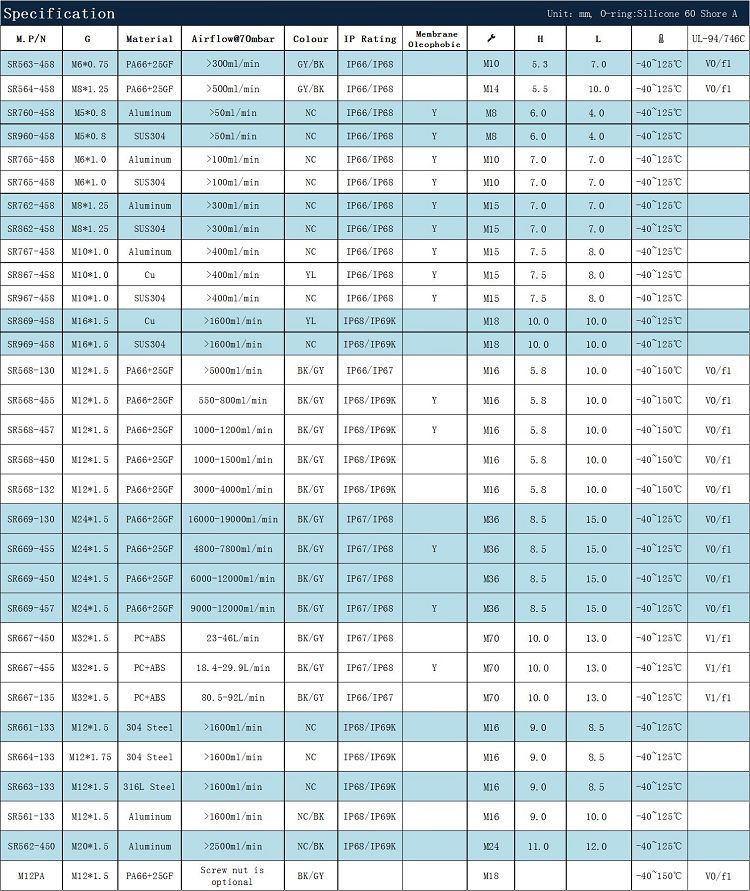

Product Specifications

Feature

1.Protective vents improve equipment reliability by preventing external factors from impacting internal electronic components of LED bulbs. This reduces failure rates and increases stability.

2.Protective vents can increase the life of LED devices by effectively dissipating heat and providing waterproof and dustproof protection, reducing environmental damage and failures.

3.Protective vents are easy to maintain due to their self-cleaning capability, which reduces equipment maintenance costs and frequency.

4.LED protection vents are highly adaptable to various settings, including high temperatures, low temperatures, humidity, and hard circumstances.

Design and Installation Tip

Vent Design: Its design needs to take into account factors such as the type of luminaire, the environment in which it will be used, and the heat dissipation requirements. For example, for high-power LED street lights, due to the high heat generation, the area and number of vents may need to be increased accordingly to improve heat dissipation efficiency; while for some small LED indicator lights, the design of vents can be relatively simple. In addition, the shape, position and orientation of the vents will also affect their ventilation and protection effects. Generally, vents are opened at locations where water is not easily accumulated, such as the top or side of the lamp housing, and reasonable ventilation paths are designed according to actual conditions to ensure that air can flow smoothly.

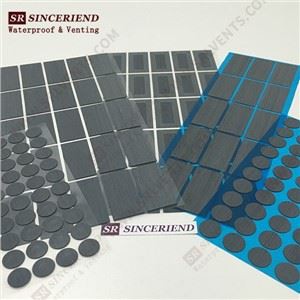

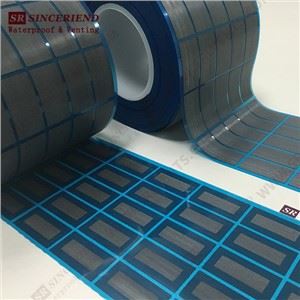

Installation method: Common installation methods include threaded connection, snap connection and glue pasting. The threaded connection method has the advantages of firm installation and easy disassembly, and is suitable for lamps that require frequent maintenance or replacement of vents; the snap connection is simple and quick to operate, which can improve installation efficiency; the glue pasting method can achieve a better sealing effect, but once pasted, it is difficult to disassemble, and is generally suitable for occasions with high sealing requirements and no need for frequent disassembly.